Used since late ‘90s in USA and Japan, HPP is one of the most innovative technologies for food treatment. In the last few decades, HPP became the leading treatment for food products thanks to some important advantages that meet the customers demand.

Non-thermal treatment, through water pressure, allows to:

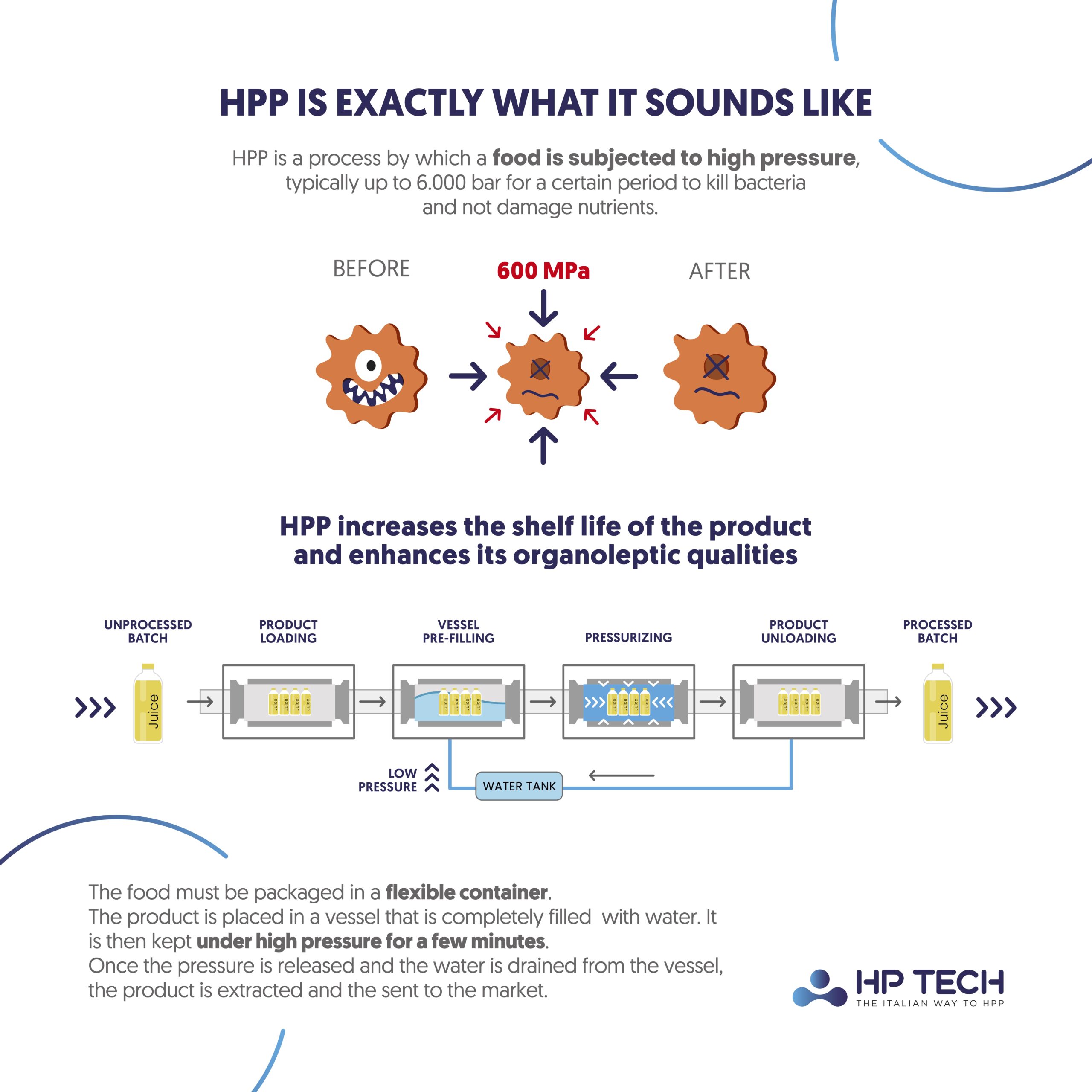

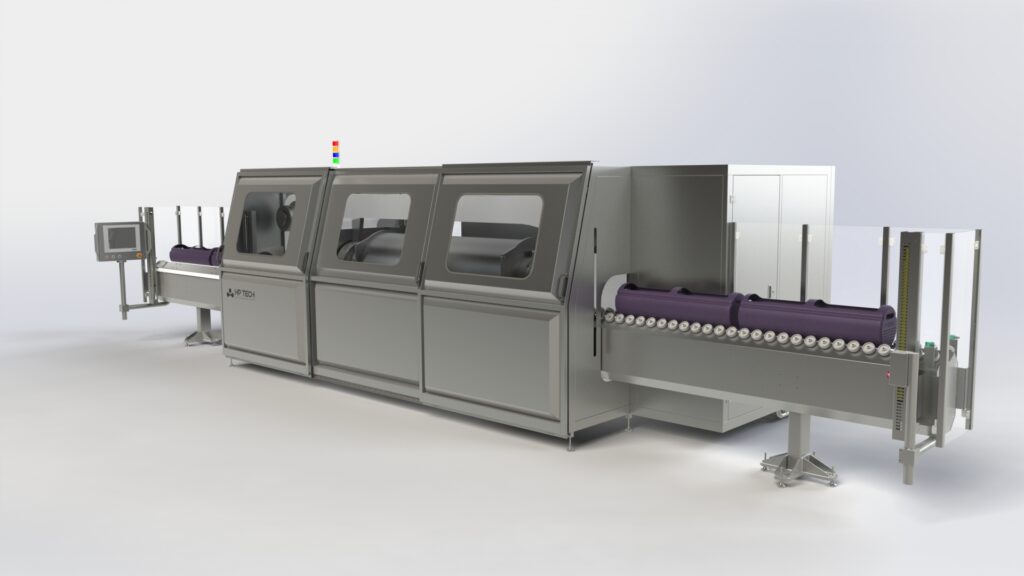

It is a technology that applies high isostatic pressure inside a sealed chamber. HPP processes the products in their final flexible packing material, to be put in a vessel which is filled with water.

The vessel pressurization starts when more water is filled, up to about 15% more water than possible. It leads to very high pressure equal to thousands of atmospheres.

Inside the vessel, the pressure is transferred to the product through water, according to the Pascal principle, in a uniform way regardless its dimensions.

At the end of the treatment, that lasts a few minutes, the vessel is emptied and the product is ready to be put on the market.

This technology has some important advantages.

Pressure is applied instantly and equally to every point of the product.

Nutritional quality of the food product remain intact

HPP inactivates pathogenic microrganisms as Salmonella, Lysteria monocytogenes, stafilococco aureus.

As the product is treated in its final packaging, a preventive disinfection of the container is not necessary

The pressurization water is recycled and the energy consumption is lower than in thermal pasteurization, both during and after the treatment.

Usually Fresh products stored at refrigerated temperature of 4°C are the most suitable for HPP treatments

Fruit and vegetables juices are perfect for HPP,

as this technology keeps the content of microelements that are thermosensitive and keeps their colour and flavour intact.

Cured meat treated with HPP can be exported;

cured meat in trays and also packaged in modified atmosphere.

HPP allows the fish products disinfection thanks to the inactivation of nematodes (Anisakis) and virus; Mollusk and crustacean shucking/meat extraction is particularly suitable for HPP.

RTE (Ready To Eat): meat, fish, vegetables,

in trays or plastic films; fresh sandwiches with different bio ingredients.

Vegetables, meat or fish Meals thanks to HPP can keep their microelements nutritional value.

Salsas, smoothies, fresh cheese, etc.

Pharmaceutical ingredients, medical devices, cosmetic products cannot accept sterilization through heat or toxic treatments as ethylene oxide.

HPP is suitable for quality meat, fish, vegetable products that cannot be sterilized, keeping their vitamins content and nutritional value,

with an extended shelf life.

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |